Department was founded in May, 1975 by Professor Yu.Ya. Meshkov. At present, the department is headed by Dr. Sci (Physics and Mathematics), Professor S.O. Kotrechko.

The department was organized on the basis of scientific team for studying speed electric heating of steel wire. This team headed by Professor Yu. Ya. Meshkov was a part of Department of Physics of Speed Electric Heating of Steels & Alloys led by Academician of A.S. Ukr.SSR V.N. Gridnev. The team was aimed on development of theoretical fundamentals & practical technology of production of cold-drawn wire for steel ropes of high strength according to essentially new technique of steel preparation to cold-drawing by speed electric hardening & electric tempering (SEHT) offered by team members. New technology has passed experimental-industrial control on Odessa Steel Wire & Rope Plant successfully in 1963–1970 (N. F. Chernenko, D. I. Nikonenko - Ph.D. in Tech. Sciences, Senior Researchers). Further increase in strength of wire for ultra-high strength ropes & special products required SEHT employment for high-carbon & alloyed steels, and it has made studying physical nature of high strength states of steels (V.G. Gavriljuk, Yu.A. Polushkin — Ph.D. in Tech. Sciences, Senior Researchers), essence of brittleness (G.A. Pacharenko — Ph.D. in Tech. Sciences, Senior Researcher), substance of catastrophic loss of ductility – lamination (G.S. Mettus — Ph.D. in Tech. Sciences, Senior Researcher) the main task of the team. This step of research has grounded fundamentals for physical nature of strength & fracture of steel. Micro-model of fracture initiation as Griffith’s nano-crack unstable equilibrium at the moment of it appearance at plastic deformation – micro-cleavage model – has been suggested. So, development of research on obtaining of ultimate strength of steels & alloys has given a rise to necessity of deep study of physical nature of strength & fracture of steels & alloys, and this, in turn, has resulted in transformation of scientific team to independent Department with new tasks in 1975. To improve existing scientific theories, members of Department continued collaboration with numerous Steel Wire & Rope enterprises (Odessa, Volgograd, Oryol, Hartsizsk, Beloretsk) as well as with defense industry enterprises (Moscow, Leningrad, Sverdlovsk) where scientific ideas, which were the basis of SEHT-technology & micro-cleavage model, has developed step-by-step to the problem of integrity of metal structures. Two State Prizes (Ukrainian SSR in 1974 & USSR in 1986) awarded to the Head of Department as a member of big group of authors was the result of above studies. Coming of the post-graduate student S.O. Kotrechko to the Department (1983) was the new step in studies of physical nature of fracture of metals & alloys. He has elaborated statistical model of crack nucleation & unstable equilibrium. It has enabled to develop physical fundamentals of fracture in extremely inhomogeneous stress & strain fields, induced by stress concentrators, i.e. under the conditions where brittle fracture is initiated within a very small regions near stress concentrators & at triaxial stress state. As a result, multiscale version of Local Approach to Fracture was offered. The effect of stochastic micro-stresses on the crack nucleus unstable equilibrium was considered in details in Ph.D. Thesis of N.N. Stetsenko (Ph.D. in Phys.-Math Sciences, Senior Researcher, 1996).

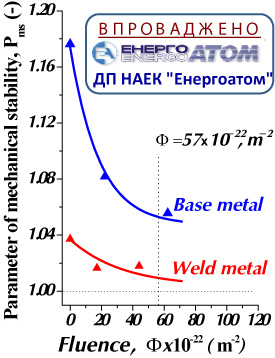

Fracture of metals in non-homogeneous force fields induced by main cracks and other stress raisers is strongly related to steel embrittlement due to “exhaust” of it toughness. So, study of physical nature of toughness, as very important mechanical property of material guaranteeing structural integrity, has become the basis of new scientific streamline of Department during the last decade. According to scientific traditions of Department, new peculiar scientific concept of nature of toughness of structural material has been proposed. It has allowed to explain for the physical essence of toughness. The main idea lies in following: metal toughness is the measure of material ability to resist transition from ductile to brittle state under the influence of embrittlement factors (stress raisers, loading dynamics, low temperature, etc.). Comprehensive measure of this property of metal was offered, so called “parameter of mechanical stability” of metal. Fundamental nature of this new characteristic of metal is that it permits to explain the effect of both micro-structural features of metal and environmental factors (temperature, loading rate, stress state, etc.) on the mechanical stability of metal. On the other hand, such approach is valid for explanation of force stability on different scale levels (macroscopic, microscopic & atomic).

1. Experimental studies include development of new physically grounded characteristics of toughness and brittle strength of metal and elaboration of techniques of their application for estimation of alloys’ ability to resist brittle fracture at loading in structures [1–5]. New mechanical characteristics of metal are offered, namely: (i) “brittle strength” RMC, (ii) “parameter of mechanical stability” Pms and (iii) “coefficient of mechanical stability” Kms. Parameter of mechanical stability Pms is comprehensive measure of toughness of structural alloy at both uniaxial and triaxial stress state and under the conditions of strongly non-homogeneous force fields induced by notches and crack-like defects. The value of Kms characterises metal’s ability to resist transition to brittle state at the simplest case of uniaxial tension.

Techniques for experimental determination of above characteristics by low-temperature tests of standard specimens (3–293 K) and notched specimens (77–293 K) are created. Regularities of influence of micro-structural parameters (ferrite grain sizes, martensite and bainitic packet sizes, carbide particle sizes, impurity sizes) on the level of brittle strength RMC are ascertained for structural steels.

Within the conception of mechanical stability, the department together with Kyiv Institute for Nuclear Research of NASUkraine and National Science Centre “Kharkov Institute of Physics and Technology” have developed the physical principles of new methodological evaluation of current state of irradiation embrittlement of RPV metal during operation of power generating unit and prediction of reactor pressure vessel lifetime [6–9].

Prediction of radiation lifetime of reactor pressure vessels WWER-1000 at A-plants of Ukraine by the criterion of loss of mechanical stability of the irradiated RPV metal.

Comprehensive study of the level of irradiation embrittlement of RPV metal of power units (No.2 of Zaporizhzhia and Pivdennoukraiinska A-plants) has been executed to ascertain the level of mechanical stability and, using standard techniques.

The possibility of safe operation of power unit No.2 at Zaporizhzhia A-plant for the period at least before finishing of project 30-years of it operation life-time has been grounded.

Theoretical studies include creation of physical theory of brittle fracture of metals and alloys. This theory is based on the conception of the crack nuclei that play the same fundamental role in brittle fracture as dislocations in plastic deformation. Starting with these ideas, statistical model of brittle fracture of polycrystalline metals was developed. It enables to explain the effect of both structure (average grain size, structure inhomogeneity, crystallographic texture etc.) and stress-strain state on the level of brittle strength of metal [10–12]. In turn, the latter has allowed to develop the concept of “computer synthesis” of optimal steel structures for specific conditions of their loading in constructions. “Multyscale Local Approach to Cleavage Fracture” [13–16] is developed in the department. Unlike conventional “BEREMIN Local Approach to Fracture”, above approach doesn’t postulate fracture probability function, and the value of fracture probability is calculated by computer simulation of the crack nuclei formation and their further unstable equilibrium. It permits to use the proposed version of “Local Approach” for prediction of the temperature dependence of fracture toughness of steel by the results of testing of small-scale specimens with circular notches, as well as for direct computer simulation of micro-structure effect on the ability of steel to resist brittle fracture at triaxial state stress and at presence of stress raisers.

2. Theoretical investigations of atomistic problems of solids’ fracture [17–20] are carried out in the Department. It is ascertained that the main specific feature of transition from elastic to plastic deformations in nano-crystal is local instability of the lattice. These investigations are aimed at elaboration of physical fundamentals of the nature of nano-crystal strength and at creation of theoretical basis for “designing” of nano-composites with known-in-advance properties. The research of atomistics of 1D crystals failure (carbyne) has, beside the fundamental, the applied value as well, which consists in development of methods for prediction of operation life-time of nanodevices.

Techniques:

- Mechanical uniaxial tensile tests over the temperature range 3…300 K.

- Impact bending tests over the temperature range 93…300 K.

- Standard tests for materials’ hardness index.

- Technique for determination of brittle strength of metals and structural alloys.

- Technique for determination of brittle strength and toughness of non-homogeneous in section armature.

- Prediction of temperature dependence of fracture toughness using “Local Approach to Fracture”.

- Modelling of the plastic deformation and fracture of crystals by method of molecular dynamics.