|

On the basis of the performed fundamental research the department has developed the following patented materials and technologies: 1. Method of heat treatment of two-phase martensite class titanium alloys Patent number 1305, Ukraine, IPC C22F1/18 2. A method for determining the optimal temperature of heating for hardening of titanium alloys Patent number 1306, Ukraine, IPC C22F1/18 3. Titanium based alloy Patent of Ukraine, number 38805A, IPC S22S14/00 4. Method of thermo-mechanical processing of high-strength beta titanium alloys Patent number 40862A, Ukraine, IPC C22F1/18 5. Method of thermo-mechanical processing of high-strength α + β titanium alloys Patent number 22693, Ukraine, IPC C22F1/18 6. The method of defect healing of deposited titanium alloys Patent number 79864, Ukraine, IPC C23S 14/68 US Patent US20060105194 (A1), European Patent EP 1662019 A1, Singapore Patent CN1776000A, Mexican Patent MX PA05012417 A 7. Biocompatible alloy with a low modulus of elasticity on the basis of Zirconium – Titanium system Patent number 102466, Ukraine, IPC A61 L 27/00 8. Method of titanium powder production Patent of Ukraine for invention number 65654, B22F9/16, C22B34/12 9. Manufacture of cost-effective titanium powder from magnesium reduced sponge US Patent No 6638336B1, Int. Cl. 10. A method of a titanium sponge hydride production Patent of Ukraine for useful model ¹ 39356, IPC C01B 6/00 11. Method of production of products made of titanium alloys Patent of Ukraine for invention number 70366, IPC B22F3/16, C22C1/04, 14/00 Patent of Ukraine for useful model ¹ 22692, IPC C22C 1/04 Patent of Ukraine for invention number 92714, IPC C22C 1/04 Eurasian patent number 018035 IPC B22F 3/16, C22C 1/04 12. Cost-effective titanium alloy powder compositions and method for manufacturing flat or shaped articles from these powders US Patent No 7993577, Int.Cl. B22F 3/16 |

Examples of practical use of technologies developed in the department

a

b High-strength (with an ultimate tensile strength (σ ≥ 1350 MPa) titanium bolts (a, - VT22 alloy) and springs (b,- VT35 alloy) for aviation application, manufactured using rapid heat treatment

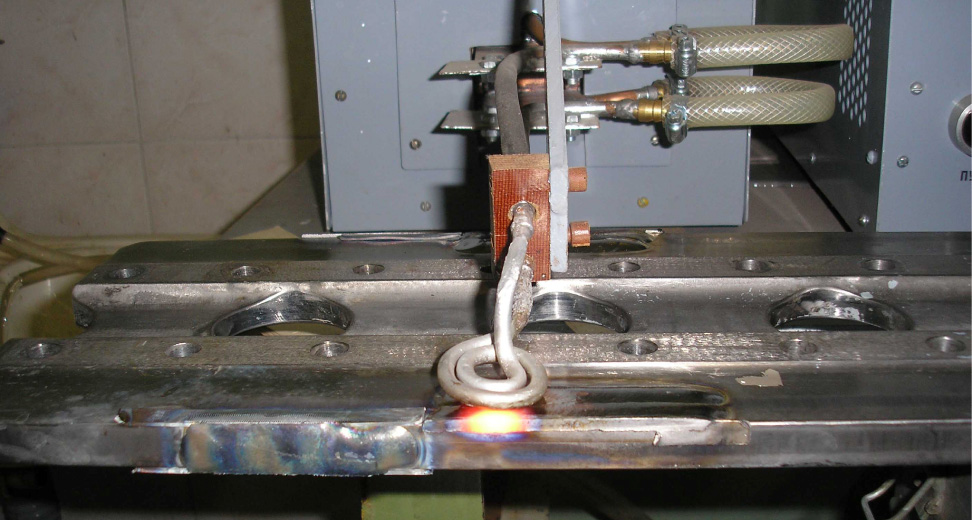

Local rapid heat treatment of the rail of the AN-124 Ruslan aircraft wing operating mechanism, renewed by surface welding

Examples of items which have been obtained in the department by the cost-efficient elemental powders method of powder metallurgy using titanium hydride |