TECHNOLOGY AND EQUIPMENT FOR ULTRASONIC IMPACT TREATMENT OF METALS

Industrial testing of the produced equipment at Kriukov Car Building Works and Toolmaker Works (Kremenchuk)

|

Areas of application:

|

|

|

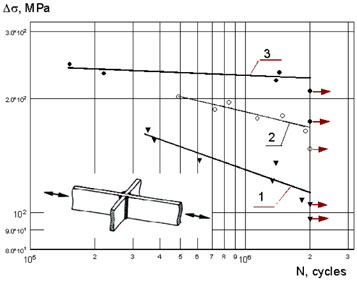

The results of fatigue tests of welded samples of low carbon steel: Portable ultrasound equipment for hardening and relaxation treatment of welded joints, power output 600 W |

|

|

|

|

Industrial testing of the produced equipment at Kriukov Car Building Works and Toolmaker Works (Kremenchuk) |

|

|

|

|

|

UIT processing of weld seams of Passenger wagon side panels of stainless steel to remove residual stresses and deviation in the plane of sheet structures. |

UIT processing of weld joints of supporting arms for wagon truck of Kyiv underground to increase the operation period of the construction. |

|

|

The application of the UIT technology increases the reliability and prolongs the operation period of metal constructions. (On the left – the UIT processing of welded crack with the length 1 m at railway bridge (Kyiv) without stopping of trains). |

The methods and equipment are protected with:

À.ñ.

AUTOMATED Equipment FOR ULTRASO NIC RESEARCH AND

DIAGNOSIS OF MATERIALS AND CONSTRUCTIONS

The equipment purpose:

The automated precision measurements in the frequency range 1-50 MHz of ultrasound velocity (US) and attenuation, as well as their changes depending on external influences (temperature, deformation, electric field, etc.), or coordinates of the sample of simple shape (billets, products). The apparatus allows, in particular, to research acoustic and elastic properties of the materials, their anisotropy, textural parameters, spatial inhomogeneity, stressed state based on textural contribution, degradation of material as a result of processing, density, etc.

|

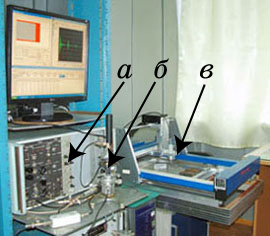

External appearance of the equipment o a - an electronic unit, á - chamber for simultaneous measurements of time delays (τ), the signal amplitude (A) and the length of the acoustic path (h); â - scanning system. |

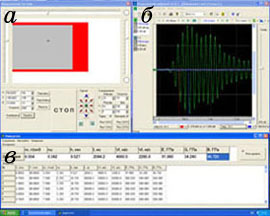

Monitor screen during measuring

a - computer panel to control the scanning process of sample by ultrasonic beam, á - the screen of the oscilloscope; â - board with the current measurements. |

The application areas:

- Scientific research of metals and alloys and other solids.

- Ultrasonic diagnostics of physical-and-mechanical and other properties of the materials and constructions connected to the velocity and attenuation of ultrasonic waves.

- US nondestructive testing (US NDT) of the products in foundry.

- Machine building.

The novelty and other advantages:

- Using a measuring chamber for simultaneous recording of time delay - τ, the signal amplitude - A and the length of the acoustic path - h.

- The ability of automatic select and tracking of time position and the magnitude of any given points of the past or reflected ultrasonic radio pulse in the sample during external influences. This makes it possible to measure the ultrasonic velocity in an inhomogeneous medium with distorted shape of the ultrasonic signal.

- Using the created software to receive and record the current data of all complex elastic characteristics of material and their changes caused by external influences. Possibility of calculating physical- and- mechanical properties related to velocity and attenuation of ultrasound, as well as a number of operation properties of the controlled objects.

Stage of development:

The working laboratory version of multifunctional ultrasonic equipment was created, which can be used for precision ultra-acoustic studies and diagnostics of metallic materials for nuclear industry and other solids. Ongoing activities to expand the fields of application of ultrasonic equipment are being carried out. On the basis of this development it is planned to create a highly specialized instruments for ultrasonic diagnostic of materials, billets and constructions for industrial use.

Application of precision pulsed ultrasound equipment

for different tasks

Devices for US NDT of materials

Welded joint zone Homogeneity of nanomaterials Diffusion layer Elastic anisotropy

The developments and methods of their application are protected with:

À.ñ. USSR ¹ 526818 dtd 30.08.76; ¹ 613236 dtd 30.06.78; ¹ 1037200 dtd 23.08.83; ¹ 1126866 dtd 30.11.84; patent of Ukraine ¹ 21827A dtd 30.04.98.